Production

We are creating and managing a global cross-brand production network. This is designed to safeguard the processes from the supplier to the factory and assembly line, and from the factory to dealers and customers. Enduring efficiency is a prerequisite for our competitiveness. We meet challenges of the future with holistic optimizations, pioneering innovations, flexible supply streams and structures, and an agile team. In fiscal year 2016, the global production volume passed the ten-million mark again. Productivity increased by around 4% year-on-year despite the continuing difficult conditions in many markets.

“Intelligently networked” production strategy

Production is supporting the future program TOGETHER – Strategy 2025 with the “intelligently networked” functional area strategy. This is the logical development of the Production Strategy 2018. It is based on the Company’s strategic development into a world-leading provider of sustainable mobility as well as on current trends such as digitalization, electrification and the changing world of work. The Production Strategy 2018 began to define key action areas and carry out successful work in these fields already in 2010. Some of the measures and topics this covered have now become part of our day-to-day business or are managed through group-wide working groups, while others have been integrated into the Production Strategy 2025 and given a new direction.

Our aim is to intelligently connect people, brands and machines, and to combine the strength and potential of our global manufacturing and logistics partnerships in order to take long-term advantage of the resulting synergies. In doing so, we can make our business even more fit for the future and competitive in the longterm.

The four strategic target areas – versatile production network, efficient production, intelligent production processes and future-ready production – guide our strategic work.

Nine strategic initiatives of our production strategy incorporate aspects such as the competitive design of our global production network, the reduction and offsetting of environmental pollution along the production process, and digitalization and its impact on the processes involved in production as well as in other work and collaboration. The fundamental aim is to increase productivity and profitability.

Production locations

The Group began the 2016 fiscal year with 119 production locations. Sitech opened a new component production site in Wrzesnia, Poland, in August. In late September, the Audi brand opened the vehicle plant in San José Chiapa, its first production facility in Mexico. In October, Scania and MAN combined their production in Saint Petersburg, while the Volkswagen Commercial Vehicles brand opened a new manufacturing site for the Crafter in Wrzesnia, Poland. MAN moved its bus production in Poland from Poznan to Starachowice. The Volkswagen Group’s global production network thus comprised 120 locations at the end of the reporting period, divided into 68 locations for passenger cars, commercial vehicles and motorcycles, and 52 locations for powertrains and components.

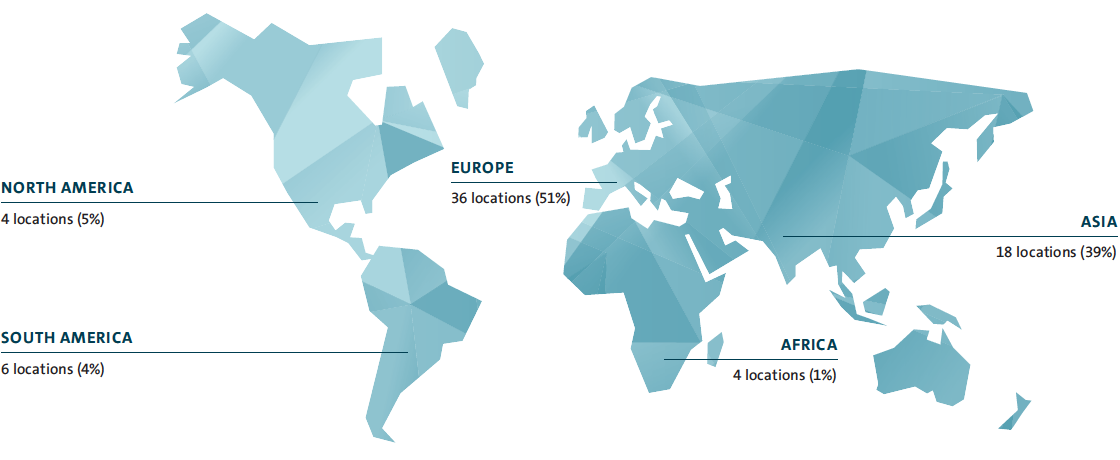

VEHICLE PRODUCTION LOCATIONS OF THE VOLKSWAGEN GROUP

Share of total production 2016 in percent

With 71 locations, Europe remains our most important production region for vehicle and component production; 28 of these sites are located in Germany alone. The Asia-Pacific region has 31 locations. In North America, we now have five locations, while the number of locations in South America remained unchanged during the reporting period at nine. The Group operates four locations in Africa.

In Europe, the plant in Wrzesnia, newly opened in 2016, is manufacturing the Crafter and has an annual capacity of 100,000 vehicles. The Portuguese plant in Palmela will also begin producing 150,000 Volkswagen T-Roc vehicles annually from the middle of the year. In Bratislava, production of the Audi Q8 will start at the beginning of 2018 with an annual capacity of 40,000 vehicles.

In order to secure and expand our market position in China, we increased capacity at the Chengdu site by 100,000 vehicles up until 2016. A further increase is planned for 2019. The new Ningbo II vehicle plant with a capacity of 150,000 vehicles per year will be opened at the end of 2017. In late 2017, capacity at one of the three vehicle plants in Anting will be increased by 75,000 units to 300,000 vehicles.

In the North America region, we plan to produce the long-wheelbase Tiguan for the US market from the first quarter of 2017.

Capacity utilization of the locations in the Volkswagen Group’s production network is further enhanced by supplying them with complete knock-down (CKD) kits for local assembly.

In September 2016, Volkswagen entered into a collaboration with Kenyan importer DT Dobie to advance the development of further emerging markets in Africa. Partial assembly of the Polo Vivo at the Kenya Vehicle Manufacturers plant began in late 2016.

At engine and transmission plants, a wide range of new, more efficient powertrains will be integrated into existing production capacity in 2017. The new evo generation of the EA211 series, for example, will launch with the four-cylinder turbo petrol engine. This is the first in a series of highly efficient petrol engines that will be produced in the medium term by at least four engine plants, largely replacing the existing generation.

New start-ups and production milestones

In 2016, the Volkswagen Group implemented a total of 62 vehicle production starts in 31 locations across 16 countries; of these, 25 were new or successor product start-ups, while 37 start-ups were attributable to derivatives and product upgrades.

The Volkswagen Group passed some significant milestones in 2016. Volkswagen Passenger Cars produced the two millionth Touran. The 25,000th e-Golf also rolled off the production line in Wolfsburg. Audi began the year by celebrating the production of 30 million vehicles worldwide and one million units of the Q5 model in Ingolstadt. At ŠKODA, the five millionth Octavia left the factory at the start of the year. The Kassel plant celebrated two milestones: the completion of three million DQ200 gearboxes helped take the total number of gearboxes produced at the site to 125 million. The MQB platform used across the Group was installed in the eight millionth vehicle in late 2016.

The Group’s production system

To help us become the world’s most sustainable, most powerful and most fascinating automotive production platform, we optimize and standardize our production processes. The Group’s value-driven, synchronous production system provides us with the necessary methodologies and instruments for this. Our goal is to further expand the Group production system throughout the world at all brand and regional locations so as to achieve sustainable and continuous improvement.

We have already made substantial progress towards achieving this goal. In the future, we will increase the amount of attention we give to further strengthening the Group’s production system and increasing its presence. Implementation is focusing on leadership, responsibility and corporate culture. As a first step in this direction, we are measuring the extent to which the methodologies and instruments are being implemented at the locations. The target/actual comparisons are used to identify fields of action. These are then defined in a project plan and worked through in a structured manner in the second step. As a synchronous company, we are including all business areas so as to systematically optimize processes.

As the complexity of products increases, a factory must work at optimal capacity so as to continue manufacturing high-quality products that give customers maximum benefits at competitive prices. This is all made possible by the standardization of production processes and operating equipment at an early stage. The basis for this is consistent construction and design principles that are defined in the form of product standards. “Concept consistency” ensures that common design principles, joining techniques and joining sequences, but also installation and connection concepts, are applied in the brands’ development and production areas. The principle of concept consistency is a fundamental component of the creation of efficient logistics and manufacturing processes.

Global production network

With twelve brands and 120 production locations, multibrand projects are an important aspect of the Volkswagen Group’s forward-looking production. The corporate objective is to generate maximum synergies based on the platform strategy and enable several brands to use the same production locations.

The modular platforms and toolkits allow us to design our production sites to be flexible. They generate synergy effects that enable us to reduce capital expenditure and make better use of existing capacities. With these toolkits, we have created the conditions for using the production sites for several brands at the same time. Our so-called multibrand locations can respond flexibly to market requirements and further raise the Group’s competitiveness. The Bratislava site, for example, produces vehicles for the Volkswagen Passenger Cars, Audi, Porsche, SEAT and ŠKODA brands. It will be joined by further multibrand locations in future, including in Tianjin, China. Currently, almost half of the 40 passenger car locations are already multibrand locations.

Another concept for volume flexibility is the “turntable”. This is used, among other things, to compensate for fluctuations in demand or in segment shifts. One such “turntable” is formed by Volkswagen’s sites in Emden (Passat), Zwickau (Passat and Golf) and Wolfsburg (Golf).

The Volkswagen Group is aiming to become one of the world’s leading providers of battery-powered electric vehicles by 2025. We will therefore expand the product range and launch a new family of electric cars based on the Modular Electric Toolkit (MEB). We are also tackling this challenge in our production processes with the aim of integrating these new vehicles into existing conventional factories as efficiently as possible. In 2016, we prepared to adapt the production network to new products and technologies in vehicle and component manufacturing.

In order to design multibrand projects and e-mobility to be cost-effective in conjunction with existing concepts, it is important to make production highly flexible and efficient.

We have begun the targeting process, standardization 2.0 and a reduction in the number of different options offered, and have hardwired these measures into the strategy. The targeting process serves the transparency and monitoring of cost types in the individual projects. Standardization 2.0 involves readjusting processes to formulate standards with an application- and user-based focus.

New technologies and product innovations

Modern, highly efficient car production like that at the Volkswagen Group would be inconceivable without reliable and extensive automation technology. Networking and digitalization in production already played an important role well before the term Industry 4.0 was coined. Volkswagen is exploring new technological solutions in many evaluation and implementation projects, including for identifying and localizing components and equipment, for energy management and predictive maintenance, for data-driven analysis and control of production processes, and for the use of wearables such as smartglasses in logistics processes. The aim is to increase equipment availability, flexibility and productivity, while also reducing the use of resources.

An important topic for the manufacturing of the future is human-robot collaboration (MRK). Volkswagen plans to support employees using robots equipped with special safety sensor technology, helping them to perform tasks that are physically uncomfortable or particularly monotonous. Assembly and logistics processes present a large potential field of application for MRK. Volkswagen is systematically analyzing the existing tasks in production lines and examining the technical abilities of the new robot systems. As part of a strategic cooperation with a renowned robot manufacturer in 2016, Volkswagen has defined a series of application projects and successfully implemented the first solutions in series production. The results of the pilot projects enable us to verify the expected ergonomic and economic benefits, and to take subsequent decisions on this basis. Volkswagen’s approach is to build its own planning expertise for workplaces with MRK.

The design and introduction of new production technologies involve the affected staff in the redesign of workplaces and processes from the very outset. This is an important prerequisite if new technologies and solutions are to find the necessary acceptance.

Environmentally efficient production

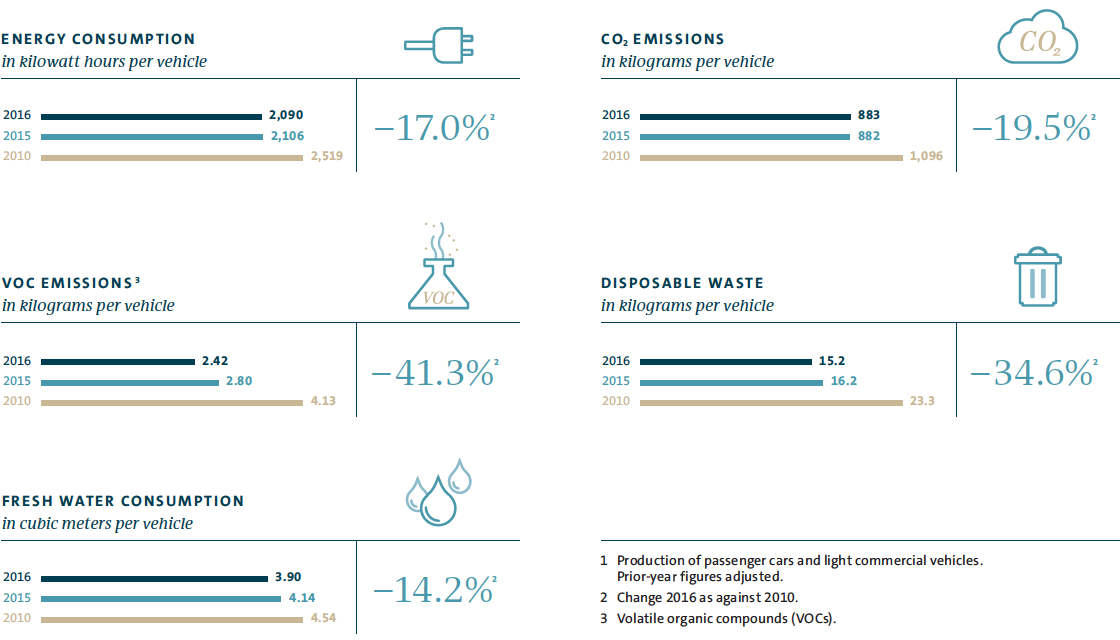

The Volkswagen Group has set itself the goal of reducing the five key environmental indicators of energy and water consumption, waste for disposal, and CO2 and VOC emissions in production by 25% for each vehicle produced – starting from

2010 levels – by 2018. This objective applies to all of the Group’s production locations and is derived from our environmental requirements for production processes, which are anchored in the Group’s environmental principles. As the charts below show, we have already made considerable progress towards reducing all these key indicators.

The Volkswagen Group’s brands contribute to achieving these goals with their own frameworks that reflect the specific features of their corporate culture and their brand image. Volkswagen Passenger Cars and Volkswagen Commercial Vehicles have established “Think Blue.Factory”, Audi has its “ultra strategy”, ŠKODA calls its program “Green Factory”, SEAT calls its program “ECOMOTIVE Factory” and Bentley’s program is called “Environmental Factory”. Porsche has introduced “resource-efficient production”. Scania and MAN are giving their commitment to the environment the names “Blue Rating” and “climate strategy”, respectively.

We are encouraging close integration and communication between the brands worldwide in order to leverage synergies. Our environmental experts meet regularly in working groups; in addition, they train our employees on the topic of environmental protection.

Volkswagen uses various analytical techniques to examine and evaluate the flow of resources and energy in production as well as the resulting environmental impact. Processes can be made more transparent with the aid of material flow analyses. These identify action recommendations to reduce both the environmental burden and production costs. Various agents can use material flow analyses. The approach can assist in planning new, more resource-efficient equipment, and act as a decision-making aid when implementing measures, and help to raise awareness among staff regarding the resource-efficient use of process materials.

We record and catalog environmental measures in an IT system and make these available for a Group-wide exchange of best practice. In the reporting period, more than 1,600 implemented measures in the area of environment and energy were documented in this system. They serve to improve passenger car and light commercial vehicle production processes. These activities are not only worthwhile from an environmental perspective; they also lead to annual savings of around €49 million.

With a series of effective, innovative measures, we once again promoted the reduction of environmental indicators in the reporting period, while at the same time improving production processes. The following examples show the extent to which the measures contribute to improvement of the production processes and achievement of the target values for the five key environmental indicators:

One important lever for reducing energy consumption is tailoring the operation of all facilities to demand. In 2016, we reinforced the energy efficiency gains from the first pilot projects on load-dependent operation of paint dryers by rolling out the technology at further locations. The change has cut energy requirements by around 7,300 MWh a year, reducing CO2 emissions by approximately 1,900 tonnes and saving some €290,000 annually.

At the Foshan factory, the biological treatment plant was expanded to include an additional membrane step. This modern technology cleans wastewater especially thoroughly, enabling it to be reused on site. The facility cleans more than 70,000 m3 of wastewater a year, reducing the factory’s environmental impact.

The Bratislava plant introduced an advanced waste management system in January 2016 to optimize waste logistics processes. Transponder technology (Data Matrix code) is used to identify waste at the point of origin and track it completely all the way to the final disposal location. At each stage of the disposal process in the factory, this documents the volume, fill level, degree of sorting, any wrongly disposed materials and the condition of container spaces. The specialist waste management department uses the information collected to develop effective measures together with the waste producers so that container volumes, collection intervals, container locations and disposal routes can be tailored optimally to production. This has achieved a 15% reduction in the quantity of cost-incurring residual waste within the space of nine months. Moreover, the time required for internal and external reporting of waste statistics has been considerably reduced and data quality increased. This waste management system also supports compliance with legal requirements for the transport and disposal of waste.

A new, environmentally friendly top coat paint line came on stream in Ingolstadt. This features ultramodern technology such as air circulation, dry scrubbing and waste air cleaning. The facility has reduced heat energy and water consumption by 20% per car. In addition, the air circulation system helps to reduce CO2 emissions per painted car by 30%. Meanwhile, the cleaning of waste air reduces VOC emissions by 90%.

Measures have also been implemented in energy generation and consumption. We have set a particularly positive example in Brazil, switching to 100% renewable energy despite the current economic difficulties in the country. This measure reduces CO2 emissions by approximately 21,000 tonnes per year.

KEY ENVIRONMENTAL INDICATORS FOR PRODUCTION IN THE VOLKSWAGEN GROUP1

Green logistics

Together, our brands, regions and plants are designing the logistics of tomorrow in a digital automotive world and using new technologies. The massive rise in available information is making processes from the supplier to the production plant to the customer more and more transparent. We use animated planning tools for designing factories and supply streams and have already implemented the tracking of loaded trucks by GPS. Our production plants work in an automated and digitalized manner with driverless transport systems in logistics.

Throughout all this, the traditional logistics objective still applies: information, material and vehicles are to be in the right place at the right time in the right quality and quantity – at the optimum cost.

Logistics is contributing to the Volkswagen Group’s increased focus on the environment, for example by analyzing the entire transport chain in respect of CO2 emissions. The objective is to avoid transports or to shift to more environmentally friendly modes of transport and to reduce fuel consumption. We are working on measures and areas of action for optimizing the logistics processes across the brands.

An important starting point for reducing CO2 emissions is the selection of the mode of transport. One of the most efficient options here is maritime transport. The Volkswagen Group is therefore involved in the Clean Shipping Network (CSN), an association of marine cargo owners. With the aid of the Clean Shipping Index rating tool, environmental efficiency figures can be compared, for example the emissions of individual ships on particular routes. This allows the environmental footprint of maritime transport to be analyzed and reduced.

The successful use of alternative drive technologies is of decisive importance in environmental and economic terms. E-mobility, gas and hybrid drives, fuel cells and other novel fuels offer interesting problem-solving approaches that are being examined for future use in logistics. To improve the environmental compatibility of vehicle transports by ship for the long term, the Volkswagen Group will use two car-carrying vessels powered by LNG (liquefied natural gas) between Europe and North America. Compared to conventional vessels, the LNG ships will reduce emissions of CO2 by up to 25%, NOx by up to 30%, soot particles by up to 60% and SOx (sulphur oxide) by up to 100% per ship and year. Furthermore, use of an ultramodern dual-fuel marine engine with direct injection and exhaust aftertreatment will deliver an additional emissions reduction.

The Volkswagen Group is constantly looking for alternatives and more environmentally friendly transport options both in vehicle and materials logistics. Materials from Turkey for the Volkswagen factory in Palmela, Portugal, have been transported by sea since late 2015. Previously, the materials travelled by truck. The change saves 240 tonnes of CO2 emissions a year and is also cutting costs for the Company.

The new logistics center in Bratislava, Slovakia, is another element in the optimization of materials transport in the Group. Optimal thermal insulation reduces heating costs, while the use of double doors in loading areas guarantees that less heat is lost. LED lighting reduces electricity consumption by some 50%. At the same time, consolidating loads enables a reduction in traffic of an average of 90 trucks for incoming goods and around 65 trucks for outgoing goods.