Research and Development

An important basis for innovation and thus the success of our business hinges on the early detection of future-oriented developments and trends in the ever-more complex areas of society, politics, technology, the environment and the economy. The Volkswagen Group’s research institutes in the world’s key automotive markets directly monitor pioneering developments in the local environment, thus gaining important insights that will safeguard the Group’s future.

In the reporting period, our research activities were focused on designing forward-looking mobility solutions that will safeguard the Company’s future and on establishing innovative technological expertise to strengthen our competitiveness. Our development activities focused on expanding our product range and enhancing the functionality, quality, safety and environmental compatibility of our products.

The future program TOGETHER – Strategy 2025 provides the framework for the realignment of our Group-wide research and development work: together with the brands, we have formulated an R&D strategy for the Group and already launched our first projects. This enables the brands to focus on developing future trends and systematically strengthening the development network – for example, so as to tap synergies and make efficiency gains even in the early phase of product development.

The Volkswagen Group’s technology management team is supporting the Group’s transformation into a provider of sustainable mobility solutions by ensuring that early development activities are aligned with future trends in the automotive sector and by creating links between innovation areas such as service design and more traditional product-related topics. All our mobility concepts are systematically tailored to our customers’ needs.

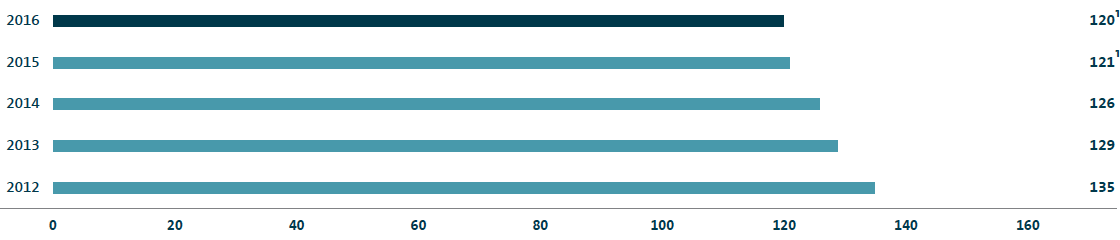

CO2 EMISSIONS OF THE VOLKSWAGEN GROUP’S EUROPEAN (EU28) NEW PASSENGER CAR FLEET

in grams per kilometer

1 Subject to official publication by the European Commission in the annual CO2 fleet monitoring report.

Fuel and drivetrain strategy

The Volkswagen Group’s new passenger car fleet in the EU (excluding Lamborghini and Bentley) emitted an average of 120 g CO2/km1 in the reporting period and was thus well below the 2016 European limit of 130 g CO2/km. As small-volume manufacturers, the Lamborghini and Bentley brands each have an independent fleet for the purposes of the European CO2 legislation and complied with their individual targets.

Starting in autumn 2017, the test procedure for emissions and fuel consumption used in the EU will gradually be replaced by the Worldwide Harmonized Light-Duty Vehicles Test Procedure (WLTP). The purpose of the new test cycle is to state more practice-oriented levels for CO2 emissions and fuel consumption and also to take account of higher speeds and driving dynamics as well as the optional equipment chosen by customers.

The Volkswagen Group’s fuel and drivetrain strategy is paving the way for sustainable, carbon-neutral mobility. The goal is to increase drive system efficiency with each new model generation – irrespective of whether the means of propulsion are combustion engines, hybrids, plug-in hybrids, pure electric drives, or fuel cell drive systems.

The drivetrain portfolio will expand and coexist between traditional drivetrains and e-mobility will increase in the future. The current modular toolkits are designed so that the full range of drive systems can be deployed and flexibly fitted on product lines across our global locations.

From today’s perspective, the combustion engine looks set to serve as the broad basis for drive technology in the coming years. In the interest of using resources responsibly, it is therefore essential for combustion engines to be further optimized.

As far as conventional combustion engines are concerned, we are continually working on technologies for the efficient purification of exhaust gases and clean combustion in order to reduce harmful emissions even further. From mid-2017 onwards, we will progressively fit all Group direct-injection TSI and TFSI engines with petrol particulate filters.

When it comes to vehicles with conventional drive systems, we have taken several efficiency-increasing measures to significantly reduce average fuel consumption. In 2016, the new V6 and V8 petrol engines were deployed for the first time in series production in the premium and sports car segment, for example in the new Porsche Panamera. These engines are not only highly responsive, but have high levels of comfort and efficiency.

Volkswagen continued to refine the TSI engine family in the reporting period. In spring 2017, the new generation made its debut with the 1.5 TSI evo engine in the new Golf. It will be followed by a BlueMotion variant with an output of 96 kW (130 PS), among others. The TSI evo underscores the Company’s strategy of using modular technology toolkits in series-production to make cutting-edge technologies available to customers.

We are expanding our traditional range of engines through drivetrain electrification. The percentage of drivers traveling predominantly short distances is growing all the time, and includes not only commuters and residents of big cities, but also drivers of delivery vehicles in urban areas. Zero-emissions, purely electric vehicles like the e-up! and e-Golf are highly suited for short-distance travel and are thus an interesting proposition, especially for this target group. In the medium-to-long term, opportunities to recharge privately – e.g. using a charging station installed on the customer’s premises – must be supplemented by good public recharging infrastructure.

However, most customers also want to be able to drive longer distances. Hybrid vehicles, particularly plug-in hybrids, combine highly efficient combustion engines with zero-emission electric motors. We consider this combination of drive concepts to be one way of offering electrified models for all mobility needs to customers of a wide range of vehicle classes, building trust in the new technologies and thus helping e-mobility gain acceptance.

All Group brands are driving the development of electric traction forwards. We have expanded our expertise in this area with the help of additional technical specialists and experts. On the basis of the experience gained with existing vehicle architectures, we designed the Modular Electric Toolkit (MEB) for the compact segment. This can be deployed across our brands in passenger cars and light commercial vehicles alike. The MEB enables us to develop very exciting vehicles and allows ranges of 300 to 600 km in purely electrical mode. It also makes it possible to factor in vehicle-specific requirements and achieve savings by combining purchasing volumes. Thanks to the Volkswagen Group’s modular toolkit strategy, modules can be deployed across different model series and brands, thus achieving substantial synergies. This applies in particular to models that share the same platform. We have integrated the production of electrified vehicles into the manufacturing processes at our existing plants, e.g. in Wolfsburg, Emden, Bratislava, Ingolstadt and Leipzig. The electric motors are manufactured at our plant in Kassel.

The battery is the heart of an electric vehicle and its energy content is the deciding factor in determining the vehicle’s range and performance. In light of the gains in market volume and unit sales of electric vehicles over the coming years, the Volkswagen Group will establish battery technology as a new competency. At the moment, we use lithium-ion cells in our all-electric and plug-in hybrid vehicles. We assemble these cells into battery systems in our Braunschweig factory. Battery types based on solid electrolytes, which have a higher energy density and offer higher intrinsic safety, are currently being researched. The next generation of electric and plug-in hybrid vehicles will be fitted with enhanced lithium-ion technology.

In 2016, we presented the visionary I.D. concept car, a zero-emissions vehicle that we intend to launch in 2020. It will have a range of up to 600 km and will be the first representative of an entirely new fleet of highly innovative electric vehicles based on the MEB. In 2016, Audi extended its range of e-tron models with the Audi Q7 3.0 l TDI e-tron quattro. In addition to this, Volkswagen Commercial Vehicles presented its e-Crafter study in the reporting period. With a driving range of more than 200 km, the first electrically powered Crafter is a near production-ready solution for zero-emissions urban delivery situations. MAN presented an all-electric MAN Lion’s City articulated bus as a modular concept vehicle, a TGS semitrailer tractor with an electric drive for inner-city night deliveries, as well as a variety of concepts for the recharging infrastructure in 2016.

As part of our future program TOGETHER – Strategy 2025, we plan to be producing more than 30 different types of purely battery-powered electric vehicles across the Group as a whole by 2025.

Alongside electric vehicles, natural-gas engines play a key role in achieving the goal of carbon-neutral mobility. Due to the chemical composition of natural gas, its CO2 emissions are around 25% below those of petrol. Volkswagen is expanding its range of eco-friendly drive concepts with the new 1.0 l three-cylinder TGI engine, which has an output of 66 kW (90 PS) and achieves impressive consumption figures and compelling performance, thanks to the systematic refinement of its combustion process and supercharging.

Renewable fuels can play a big part in further reducing the CO2 emissions of combustion engines and can complement e-mobility, e.g. on long-distance trips. They are also a fast way to cut the overall CO2 emissions of vehicles already on the road. Volkswagen plans to deploy and refine existing fuel solutions in a model region and to test new approaches. Beyond that, the Company is taking part in joint projects that examine the potential to produce petrol, diesel and gas from renewable energy sources. In 2016, Audi expanded its production capacity for sustainably generated e-gas and set a milestone with Germany’s first power-to-gas facility using industrial-scale biological methanation. Furthermore, Audi unveiled another g-tron model. Like the A3 g-tron and the A4 g-tron, the Audi A5 Sportback g-tron can be operated with either climate-friendly Audi e-gas or natural gas (CNG) or with petrol.

Hydrogen will not be widely available as a fuel in the medium term. Both hydrogen filling stations and renewable hydrogen production plants will have to be constructed. Volkswagen has been working on fuel cell technologies for many years and has gained extensive experience operating test fleets. In the reporting period, Audi provided a concrete perspective of its hydrogen drives, presenting the h-tron quattro concept car, a hydrogen-powered sports SUV that can be completely refilled with hydrogen in about four minutes and has a range of 600 km.

Life cycle engineering and recycling

Innovations and new technologies for reducing fuel consumption are not enough on their own to minimize the effect of vehicles on the environment. That is why we examine the entire product life cycle of our vehicles – including the production of both raw materials and components – and prepare life cycle assessments in accordance with ISO standards 14040 and 14044. On this basis, we can determine where improvements have the greatest effect and develop innovations that target these points directly. We call this life cycle engineering.

The Volkswagen Passenger Cars brand reports on the results in so-called environmental ratings. These ratings show the ecological advances in new vehicle models compared with their immediate predecessors. Audi publishes this information under the term “environmental footprint”, while SEAT provides corresponding data in its product catalog. We also use life cycle assessments for the special subject of water, using them to calculate and analyze the amount of water consumed by a vehicle throughout its entire life cycle (water footprint). This enables us to take targeted action to reduce water consumption. We also use the results of our life cycle assessments to generate the Scope 3 inventory. We report on CO2 emissions in twelve out of a total of 15 Scope 3 categories in accordance with the Scope 3 standard published by the World Business Council for Sustainable Development (WBCSD) and the World Resources Institute. As a result, we are one of the leading companies in the automotive industry. You can find further information on this in the Volkswagen Group’s Sustainability Report 2016.

As we wish to minimize our vehicles’ impact on the environment in collaboration with our suppliers, Volkswagen joined the CDP supply chain program in 2015; this records greenhouse gas emissions throughout the value chain. We seek direct contact with our suppliers in specific workshops, where together we discuss and develop innovative approaches to the ecological optimization of particular components.

Recycling, too, is central to reducing the impact of our products on the environment and conserving resources. It is not just a matter of recycling vehicles at the end of their service life: we already pay attention to the recyclability of the required materials, the use of high-quality recycled material and the avoidance of pollutants when developing new vehicles. Therefore, our end-of-life vehicles are 85% recyclable and 95% recoverable. We also factor in aspects of the use phase, for instance the treatment and disposal of service fluids or high-wear components.

Building on the findings of the LithoRec research project (lithium-ion battery recycling), we are working on extending the useful life of such batteries and the recirculation of battery materials so as to conserve resources and cut costs. There is also the Volkswagen Passenger Cars brand’s Genuine Exchange Parts program, whereby industrial reconditioning produces high-quality exchange parts that conserve resources and offer the same quality, functionality and warranty, but are on average 40% cheaper than the corresponding new parts.